Shop all

Our materials

Shop

New in

Categories

Our fabrics

COMING SOON

Upcoming launches

Future projects

Come to see us

Hello we are Patine

Welcome to the top of your drawer pile, the clothes you'll still want to wear in 2037. We're creating with you a new brand model, somewhere between the nostalgia for the carefree 80s and the utopia of a future where we'll have curbed global warming.

Inside Patine

The brand

Conscious Patine

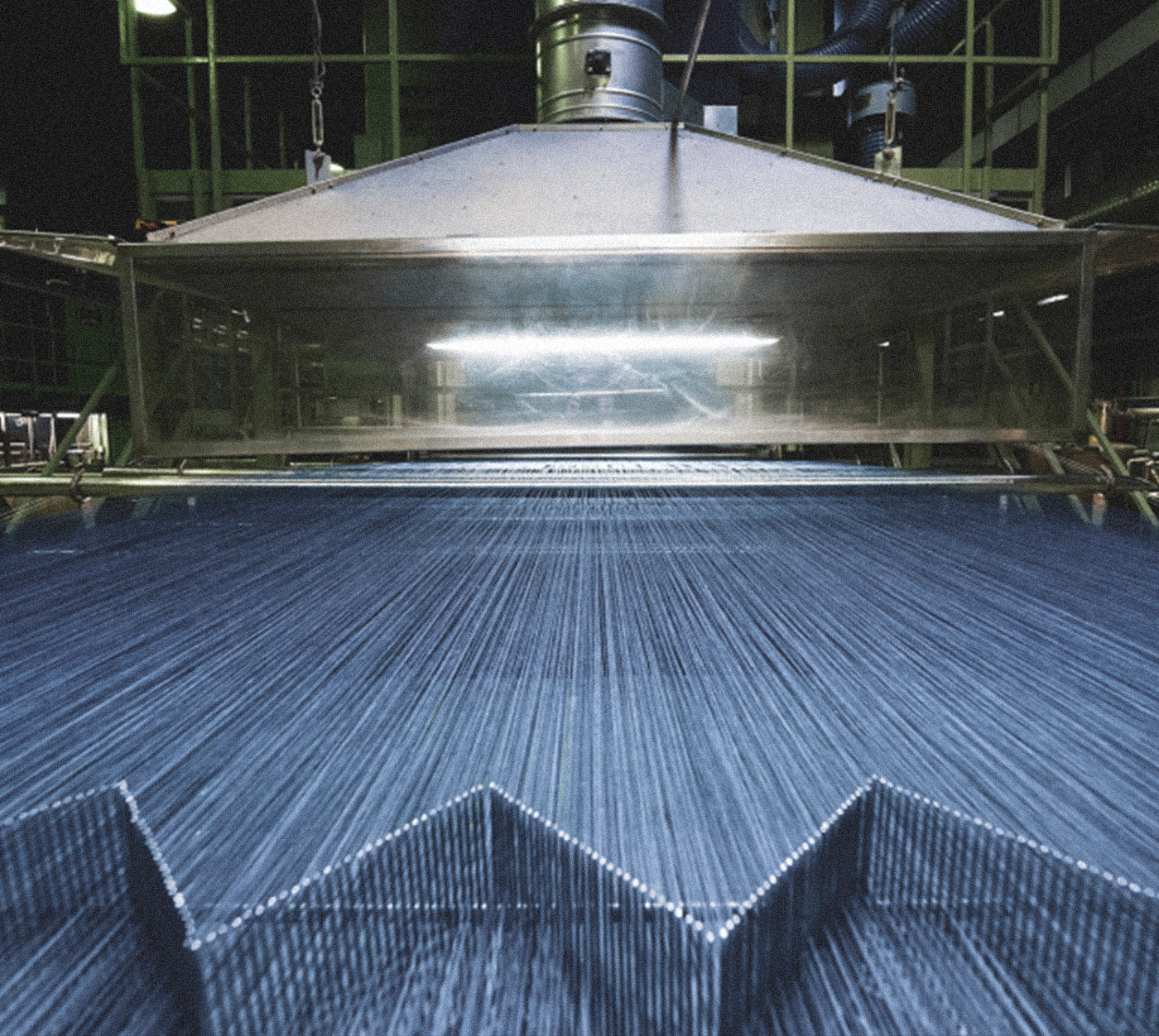

Our Fabrics